Reconditioning a Cummins engine is an art, and not all garages are at the same level.

Why choose to have your engine rebuilt with us?

Because Dodge Ram Cummins are our specialty.

Our specialists have refined the SML Diesel Performance technique over time. They rebuild engines of excellent quantity that charm their owner with their unique sound and unparalleled performance.

We also have rebuilt Cummins to swaps in trucks from other manufacturers such as Ford, GMC and International.

For industrial machinery and swaps in small SUVs we rebuilt 4BTs.

CUMMINS 4BT 3.9L

CUMMINS 6BT 12V

CUMMINS QSB 4.5L

CUMMINS ISB 5.9L

CUMMINS ISB 6.7L

Thoroughness and precision are the guarantee of a Cummins engine rebuilt by the SML Diesel Performance team.

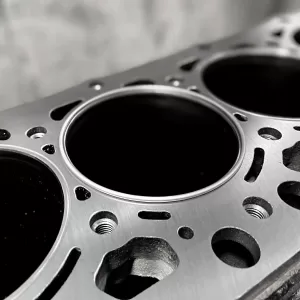

ENGINE HEAD

GIVE A 2ND LIFE TO YOUR CUMMINS

WANT TO GIVE MORE HP TO YOUR CUMMINS ENGINE?

Do you dream of building the truck of your dreams?

When you’re rebuilding your Cummins head or engine, it’s a good time to think about what components you can upgrade to increase its reliability and power.

Your truck is powered by a chain of reactions. Some components are modified to improve performance, others are replaced to improve their ability to withstand the new power.

It’s important when you increase the power of your truck to maintain the balance so that your engine develops the maximum HP.

WITHSTAND THE ADDITIONAL STRESS CREATED BY ADDING HORSEPOWER AND TORQUE

FIRE RINGS STAGE 1

FIRE RINGS STAGE 1

Above 40 lbs of boost, the original head gasket performance decreases dramatically. The solution: machine grooves in the motor head to install fire rings, thereby increasing additional compressive strength on the head surface.

HEAD STUDS

HEAD STUDS

To keep the pressure in the cylinders, we install performance head studs, tested to 220,000 PSI of stretching effort. They increase pressure on the gasket and hold the engine head securely in place. This modification is essential with the installation of fire rings.

VALVE SPRINGS

VALVE SPRINGS

In order to prevent the compression from escaping from the cylinders, we install stiffer valve springs. They maintain higher pressure on the valves, preventing them from floating at high revs.

PUSHRODS

PUSHRODS

To prevent the pushrods from deforming, we install pushrods with thicker tubes. They are able to better withstand the higher pressure of the valve springs.

BETTER STRETCH AND COMPRESSION ABILITY

FIRE RINGS STAGE 2

FIRE RINGS STAGE 2

When you build a truck capable of developing 600HP and more, the stress on the head gasket is at its maximum. Stage 2 fire rings (the groove machining is split 50/50 between the head and the engine block) will keep your engine head in place.

CAMSHAFT

CAMSHAFT

Due to performance modifications, the exhaust temperatures increase. Installing a performance camshaft will allow the valves to open a bit more, allowing air to flow in and out of the cylinders more efficiently. It is the shape of the lobes that makes a big difference and as a bonus, the HP increases slightly.

TAPPETS

TAPPETS

The contact surface of the tappets must be perfectly straight to sit well on the camchaft and avoid damaging the cam lobes. It is for this reason that each time we change the camshaft, we also change the tappets.

RODS

RODS

Regarding the rods, there are 2 possibilities of rods that can support the new engine power. Installing RAM rods made before 2003 can take more stress because instead of being cracked, they are machined. You can also install performance rods, made from a harder alloy and resistant to greater torsion force.