The Essential Guide: Cummins ISB 6.7L Turbo Problem – Symptoms, Diagnostics, and Solutions

The performance of your Dodge RAM is crucial to your driving experience, especially with a Cummins ISB 6.7L engine. When the turbo or the actuator starts to weaken, it can have a direct impact on your truck’s performance.

In this article, we’ll take an in-depth look at common turbo problems, how to diagnose them, and which solutions are available to you. Keep reading to make sure your Dodge RAM stays powerful and reliable, ready to tackle every challenge.

Warning Signs of a Turbo Problem

Loss or Lack of Power

One of the first signs that your turbo might be experiencing a problem is the appearance of a check engine code on your dashboard. After that, you may notice a loss or lack of power in your Dodge RAM. If your truck struggles to accelerate or doesn’t respond as well as it used to, it could indicate that the turbo isn’t functioning properly.

The turbo plays a crucial role by increasing the pressure and amount of air entering the engine, which improves combustion and boosts power. When the turbo fails, the engine receives less air, leading to decreased power. It’s therefore essential to pay attention to these signs and have the turbo inspected as soon as possible to avoid further damage.

Abnormal Turbo Whistle

Another revealing sign of a turbo problem is an abnormal whistle. Under normal conditions, a healthy turbo may produce a slight whistling sound, especially when running at full capacity. However, a louder or unusual whistle can indicate an air leak in the boost system or internal damage to the turbo.

This leak can occur around the hoses, fittings, or seals in the system. If you hear this type of noise, it’s crucial to have the turbo inspected to identify and fix the source of the issue before it worsens.

Excessive Smoke: Black Exhaust Smoke

The appearance of excessive exhaust smoke, especially black smoke, is another classic sign of a turbo issue. This black smoke is often caused by excess unburned fuel in the exhaust gases. When the turbo isn’t working properly, it doesn’t supply enough air to fully burn the fuel, resulting in incomplete combustion.

This situation not only points to a faulty turbo but can also lead to pollution problems and reduced engine efficiency. If you notice black smoke coming from the exhaust, have your turbo inspected right away.

Increased Fuel Consumption

A failing turbo can also lead to a noticeable increase in fuel consumption. The turbo’s role is to improve combustion efficiency by increasing the amount of air entering the engine.

If the turbo isn’t functioning properly, the engine compensates by injecting more fuel to try to maintain performance, which results in higher fuel consumption. If you find yourself refueling more often without changing your driving habits, it could be a sign that your turbo needs to be inspected and possibly replaced.

These symptoms can alert you to potential issues with your Cummins ISB 6.7L turbo. Early detection and quick action can help prevent more severe damage and keep your Dodge RAM in top running condition.

How to Diagnose a Turbo Problem

- Check Engine Codes

The first step in diagnosing a turbo issue on your Dodge RAM is to check the engine codes. These codes are generated by the onboard computer (ECM) when something isn’t functioning properly. To do this, use an OBD-II code reader to scan your truck’s system. This will give you a clear idea whether the potential problems are related to the turbo or other components.

The Most Common Codes: P0046, U010C, P266C

Code P0046: This code indicates an issue with the turbo boost control circuit. It may be caused by a faulty actuator, corroded electrical connections, or an internal turbo problem.

Code U010C: This code signifies a loss of communication with the turbo actuator control module. It could be due to defective wiring, a failing module, or connection issues.

Code P266C: This code shows that the actuator is forcing the turbo to move, often suggesting that the turbo needs to be replaced. This issue can be related to a faulty actuator or a jammed VGT (Variable Geometry Turbo) mechanism.

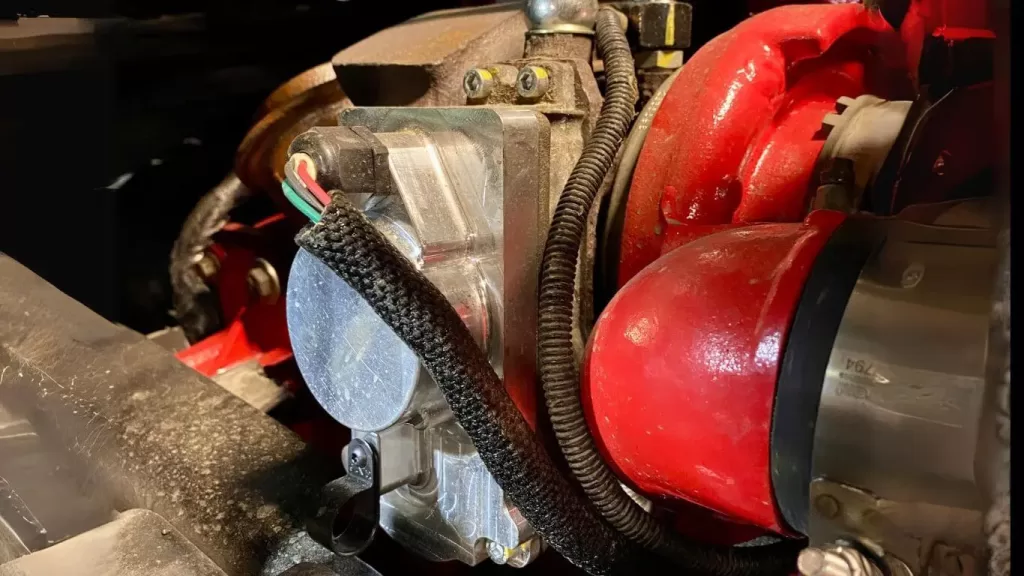

- Inspect the Actuator and the VGT Mechanism

After checking the engine codes, it’s important to inspect the actuator and the VGT mechanism to identify the source of the problem. The VGT is a crucial component of the turbo that adjusts the geometry of the vanes to optimize engine performance.

Remove the Turbo Actuator

To inspect the turbo, you need to drain the coolant using the valve on the radiator, and then you can remove the actuator. This will allow you to take a closer look at the mechanism and check if it’s stuck or difficult to move. Use the proper tools and follow the instructions in the service manual to avoid damaging the components.

Check the VGT Lever

Once the actuator is removed, check the VGT lever. This lever should move freely without resistance. If you find that the lever is stuck or difficult to move, it indicates an issue with the VGT mechanism. On the other hand, if the lever operates correctly, the problem is likely with the actuator itself. In either case, it’s crucial to repair or replace the defective components to restore optimal turbo performance.

Options to Resolve the Problem

- Replace the Turbo

When the diagnosis indicates that the turbo is faulty, a complete turbo replacement may be the best solution. Here are the available options:

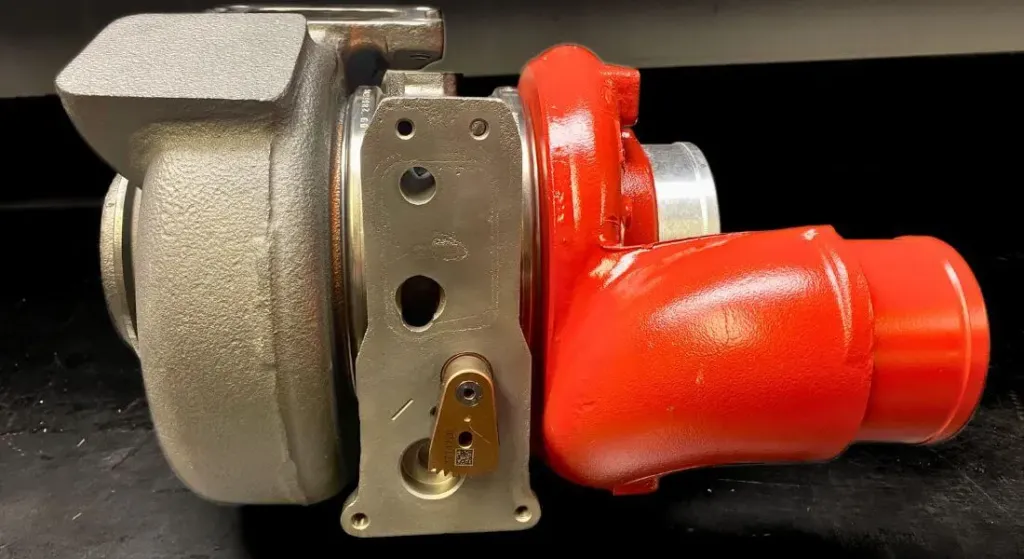

Install a Reman Turbo with a “Tested” Holset Actuator

Some suppliers offer a remanufactured turbo with a Holset actuator without clearly stating that it is actually a “tested” actuator—used, cleaned, and verified. The only way to identify this option is often its very attractive price, significantly lower than other offers. If your budget is tight, this may be an option to consider, but it’s important to understand the implications:

Advantages:

- Most affordable option: Often the lowest price, making it practical if you’re looking for a quick and cost-effective solution.

- Easy installation: Typically pre-assembled, which simplifies the process.

- Initial performance: Allows you to get your truck back on the road even with a limited budget.

Disadvantages:

- Unknown history: The actuator has already been used, and its previous conditions or precise state are unclear.

- Uncertain lifespan: Even if tested, accumulated wear can lead to premature failures.

- Lack of transparency: The product is often marketed as a reman turbo with a “Holset actuator” without mentioning that it has merely been “tested.”

- Potential additional costs: If the actuator fails quickly, you’ll need to reinvest in repairs or replacements.

Ultimately, this option may work if your budget doesn’t allow for a more expensive model. Just be sure to ask questions about the origin and actual condition of the actuator to make an informed decision.

Install a Reman Turbo with a New Holset Actuator

Advantages :

- Reliable performance: A new actuator ensures better reliability and a longer lifespan.

- Cost-effective: Less expensive than a brand-new turbo with a new actuator while providing comparable performance.

- Possible warranty: Remanufactured turbos often come with a warranty, offering additional peace of mind.

Disadvantages:

- Higher cost than the first option: While cheaper than a completely new setup, this option is more expensive than installing a “tested” actuator.

- Reconditioned turbo: Some people prefer brand-new parts over remanufactured ones, even though the quality is generally comparable.

- Calibration required: It’s important to note that this option requires calibration to ensure proper functionality.

Install a Remanufactured (Reman) Turbo with an HD Actuator

For maximum performance, a remanufactured turbo with an HD (Heavy Duty) actuator is an excellent option. These actuators are designed to withstand more demanding operating conditions.

Advantages:

- Superior durability: The HD actuator is built for intensive use, making it ideal if you operate your truck in demanding conditions.

- Enhanced performance: Offers better responsiveness and overall turbo performance.

- Extended lifespan: Reinforced materials and robust design ensure a longer service life.

- No calibration required: The HD actuator calibrates itself automatically every time you turn the key, eliminating the need for manual calibration during installation.

Disadvantages:

- Higher cost: More expensive than the first two options, but justified by the HD actuator’s superior quality.

- Limited availability in some garages: While HD actuators are generally accessible, not all garages offer them. This may require finding a specialized shop or ordering the part yourself.

Learn more about Reman Turbo:

Install a New Turbo with a New Holset Actuator

Opting for a new turbo with a new Holset actuator ensures optimal performance without the need for calibration.

Advantages:

- Maximum performance: Brand-new components ensure that your turbo system operates at its highest level.

- No calibration required: Simplifies installation and reduces labor time.

- Increased reliability: Lower risk of early failures, providing long-term peace of mind.

- Comprehensive warranty: Typically comes with a manufacturer’s warranty covering both the turbo and the actuator.

Disadvantages:

- Highest cost: This is the most expensive option, which may not fit all budgets.

- Significant initial investment: Can be a considerable expense, especially if your truck is older.

2. Replace the Actuator: The Variable Geometry Turbo Controller

If the turbo is functioning properly but the actuator is faulty, replacing only the actuator may be enough to solve the issue. Here are the available options:

Replace with a New Holset Actuator

A new Holset replacement actuator can be an economical and effective solution. However, it requires calibration to work correctly with your existing turbo.

Advantages:

- Lower cost: Less expensive than purchasing a complete turbo or an HD actuator, making it ideal if you’re on a budget.

- OEM quality: Choosing an Original Equipment Manufacturer (OEM) part ensures compatibility and high-quality performance.

- Reuse of existing turbo: If your turbo is still in good condition, this option allows you to extend its lifespan without replacement.

Disadvantages:

- Calibration required: The new actuator must be calibrated with the existing turbo, potentially leading to additional costs for calibration services.

- Challenges with an older turbo: If your turbo is worn or shows signs of aging, calibration may be complicated or ineffective, potentially requiring a turbo replacement later.

Learn more about Holset actuators:

Replace with an HD Actuator

Advantages:

- Superior performance: The more powerful motor in the HD actuator can handle stiffer turbo levers, providing better responsiveness and improved overall performance.

- Increased durability: Designed for more demanding operating conditions, the HD actuator offers superior longevity.

- Simplified installation: Without the need for calibration, the installation process is faster and easier.

Disadvantages:

- Higher initial cost: The HD actuator is slightly more expensive than a standard new Holset actuator.

- Availability in some garages: Not all garages offer the HD actuator, which may require ordering in advance or finding a specialized shop.

Learn more about HD actuators:

The options for resolving a Cummins ISB 6.7L turbo issue vary depending on the specific diagnosis and the preferences of each owner. Whether you choose to replace the entire turbo or just the actuator, it’s crucial to select the solution that ensures the best performance and highest reliability for your Dodge RAM. By making an informed decision, you can keep your truck in optimal condition and avoid future problems.

An Additional Option: The “Second Gen Swap”

Advantages:

- Larger turbo: You can install a turbo with a size exceeding 64.5 mm to achieve greater performance.

- Reduced maintenance issues: By choosing a non-VGT turbo, you permanently eliminate problems related to the exhaust brake.

- 5″ downpipe: With a larger turbo, you can also opt for a 5-inch downpipe to improve exhaust flow.

- Ideal for a competition truck: This setup is perfect if you’re building a race truck or aiming for extreme performance.

Disadvantages:

- Higher cost: This type of turbo usually comes with a manifold and a new downpipe. You’ll also need to account for labor costs and reprogramming your truck.

- Less suitable for towing: If you need to haul heavy loads, the VGT provides significant advantages in performance and control, especially with the exhaust brake.

Preventing Actuator Problems on a Cummins ISB 6.7L Turbo

Use Your VGT as Your Exhaust Brake

For 2012 and Older Models: Activate the Exhaust Brake at Every Startup

If you own a 2012 or older Dodge RAM, it’s recommended to activate the exhaust brake at every startup.

- Press the button once to enable automatic mode: the VGT activates when you press the brake pedal or when the truck’s computer determines it’s necessary.

- Press the button twice to enable full mode: the VGT engages as soon as you release the accelerator.

This practice keeps the VGT components in constant motion, preventing carbon buildup that could block or damage the actuator. It’s also possible to modify the programming so that the VGT activates automatically when the truck starts.

Advantage: Regular use of the VGT helps prevent problems.

Tip: Make sure to activate the exhaust brake as soon as you hit the road to maximize its preventive benefits.

For 2013 and Newer Models: Activate Automatic or Full Mode Just Once

For 2013 and newer Dodge RAM models, you only need to activate the exhaust brake once. Once activated, this mode remains permanently enabled, ensuring continuous use of the VGT every time the vehicle starts.

Advantage: Simplifies exhaust brake management and ensures constant prevention of actuator problems.

Tip: Activating the exhaust brake, whether in automatic or full mode, is a one-time task that provides long-term benefits, reducing the risk of actuator and turbo malfunctions.

By adopting these preventive practices, you can significantly reduce the risk of problems with the actuator and turbo on your Cummins ISB 6.7L. Regularly using the VGT as an exhaust brake and following the specific recommendations for your truck model will help maintain your vehicle’s performance and reliability. Preventive maintenance and careful use are key to avoiding costly breakdowns and extending the lifespan of your Dodge RAM.

Quickly Diagnose Potential Problems to Avoid Costly Breakdowns

Keeping your Dodge RAM with a Cummins ISB 6.7L engine in perfect running condition requires careful attention to early signs of turbo and actuator issues. By recognizing symptoms such as loss of power, abnormal whistling, excessive smoke, and increased fuel consumption, you can quickly diagnose potential failures. With the repair and replacement options outlined here, you have all the information you need to choose the solution that best fits your budget and performance needs.

Additionally, by adopting simple preventive practices, such as regularly using the exhaust brake, you can extend the lifespan of your turbo and actuator, reducing the risk of costly breakdowns. In the end, preventive maintenance and prompt action are key to ensuring the reliability and performance of your Dodge RAM.

If you have any doubts or additional questions, don’t hesitate to consult a professional. Take care of your truck, and it will reward you with optimal performance for years to come. Thank you for reading, and safe travels with your Dodge RAM!